Sources: Concrete-AI, Los Angeles; CP staff

Mix design software developer Concrete-AI has raised $2 million in a seed financing round with participation by the Grantham Foundation for the Protection of the Environment, a prominent family office, and other marquee investors. The investment will accelerate rollout of the firm’s pioneering data science platform that uses artificial intelligence (AI) and machine learning (ML) to optimize supply chains and materials selection, and bring new efficiencies to concrete mixture design, proportioning and production. The platform delivers unparalleled reductions in the cost and embodied carbon of ready mixed and precast concrete without changing production methods or materials.

Concurrent with the financing round, Concrete-AI appointed Ryan Henkensiefken as vice president of Business Development, who arrives after more than a decade in concrete and chemicals. Most recently, he was market development manager for Master Builders Solutions, transitioning to that role after serving in business development and engineering capacities for Central Concrete Supply, a U.S. Concrete company.

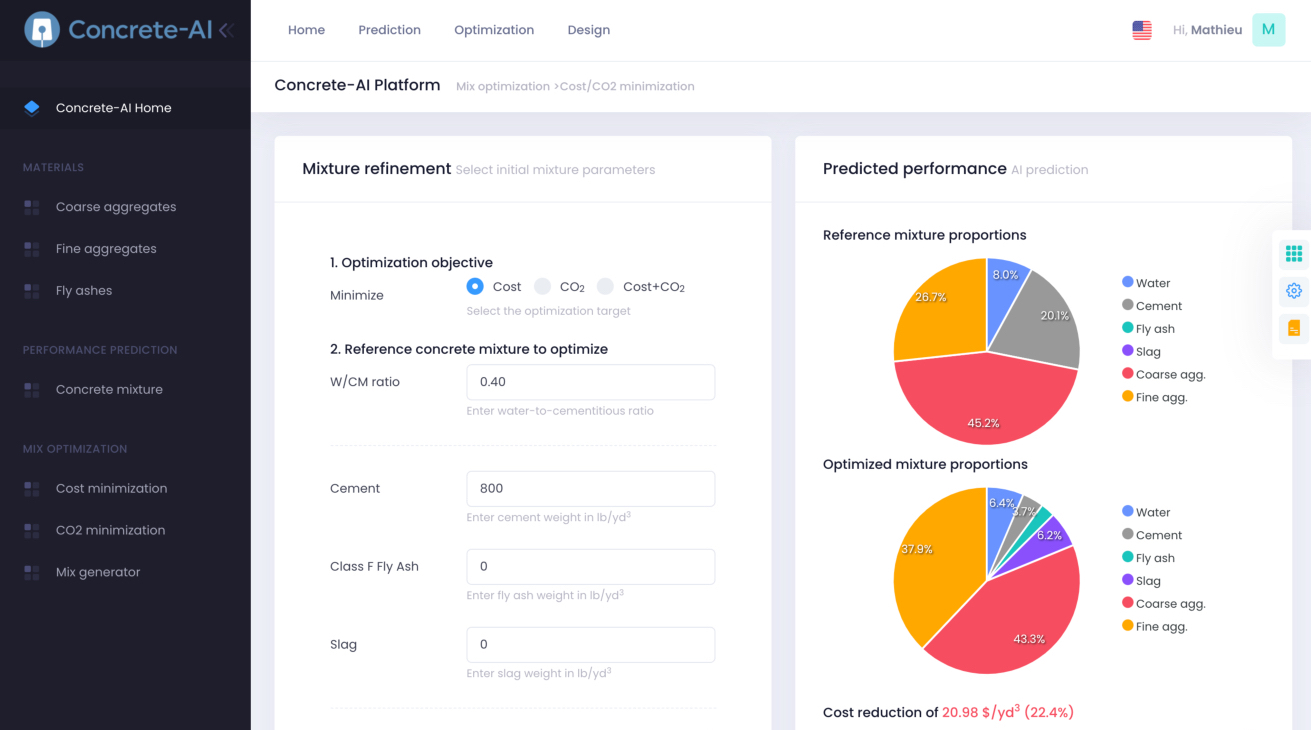

Henkensiefken will assist Concrete-AI colleagues engaged in pre-commercial platform piloting with several of the largest cement, concrete and chemical admixture producers, including Summit Materials; U.S. Concrete, a Vulcan Materials company; and, Votorantim Cimentos (Prairie Material). The platform has been shown to reduce ready mixed concrete material costs and embodied carbon footprint by up to 10 percent and 50 percent, respectively. It achieves these reductions by applying AI/ML-enabled optimization to predict the performance of concrete as a function of its mixture proportions, and the characteristics of coarse or fine aggregates, supplementary cementitious materials, plus chemical admixture type and dosage. The result is a highly optimized, cost-effective concrete that fulfills all engineering performance characteristics such as slump, set time and strength, while utilizing locally available raw materials to ensure safety, longevity and code compliance.

Concrete-AI’s AI/ML approach for mix proportioning helps solve some of the biggest challenges producers face: concrete overdesign; embodied carbon level attributable to cement; increasing material cost; and, diminishing margins. Traditionally, because it has been difficult to predict how the constituents of a mixture will affect finished slab or structure performance, concrete formulations have been overdesigned such that they contain excess cement. In the U.S. alone, Concrete-AI contends, this tendency costs the industry more than $1 billion annually and results in 10 million tonnes of incremental carbon dioxide emissions associated with cement production. If Concrete-AI were adopted globally, annual CO2 emissions from cement and concrete production could be reduced upward 500 million tonnes.

“Concrete-AI offers the construction sector a one-of-a-kind, capital-light, rapidly deployable, Software-as-a-Service (SaaS) solution that brings new performance and sustainability efficiencies to concrete production while leveraging existing supply chains, manufacturing processes, and the power of data,” says CEO Alex Hall. “To reduce the embodied carbon footprint of concrete construction projects, we must use materials effectively and efficiently. Concrete-AI enables this while ensuring safety, peak engineering performance and sustainability by optimizing the use of cement, aggregates, and diverse SCMs in concrete, in an unparalleled manner by a data-driven approach. At a time when states and the federal government are increasingly requiring and incentivizing the reduction of embodied carbon in the built environment, Concrete-AI offers the industry the leading data-driven solution for ensuring cost-effective and sustainable construction.”

The core Concrete-AI technology was developed at the University of California, Los Angeles’ Institute for Carbon Management (ICM) by Gaurav Sant and Mathieu Bauchy. Both are faculty members of UCLA Samueli School of Engineering in the Departments of Civil and Environmental Engineering. Professor Sant is also a Department of Materials Science and Engineering faculty member and ICM director.

Related articles

Holcim veteran takes helm of low carbon and QC driven Concrete-AI

Artificial intelligence drives mix design performance, CO2 profiles